Screening equipment is the important operational system for pulp processing. After separation of the black liquor from the fiber in the washing section the pulp contains coarser fibers, foreign matter and dirt as like pieces of bark, digester brick, cement etc. Hence this unwanted and troublesome matter should be removed to produce first quality pulp. Pulp screening equipment is applied in this regards.

There are two categories screens are used in pulp mills; coarse screens and fine screens. These screening equipment works basis on vibrating, shaking, gravity centrifugal and centripetal forces.

The major types of coarse screen are two types sliver screens and knotters. The examples of sliver screens such as bull screen, rotary scraper, rotary oscillating and the knotters such as worm knotter, Johnson knotter screen, diaphragm screen etc.

On the other hands, the major types of fine screen are Cowan, IMPCO, diaphragm or flat screen, Quiller, bird pulp screen, vertical type of centrifugal screens, inward-flow rotary type screen, bird inward-flow screen, Jones inward flow screen, Walpole outward flow screen, APMEW outward flow, APMEW inward flow, Ahlfors Swedish screens etc.

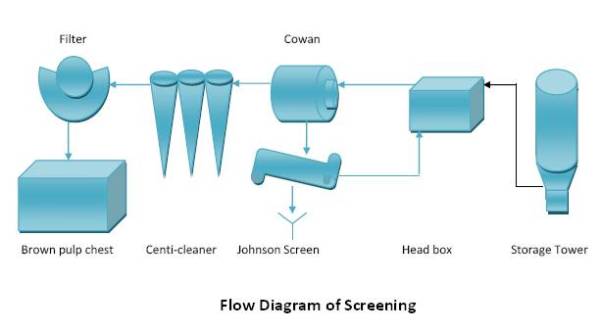

A simplified “cascade arrangement” of screens is shown in Figure below:

Screen selection

Screen selection is a significant matter. All type of screen is not suitable for all kinds of fiber. To choice a screen it should be consider the kind of fiber, cost and repair, power consumption, efficiency, capacity, space required etc.

Various factor affects on screening performance

There are various factor that effects on screening performance such as stock consistency, type of fiber, type and size of holes, type of plate cleaning mechanism, level of coarse fiber and foreign matter, rejection rate, flow configuration, flow rate, stock temperature etc.

Water (consistency) has an important function in whole the steps in the pulp screening. In screening section, water acts as a conveyer for the fiber. The consistency of the pulp of the storage tanks may be 3 to 4 percent. When the pulp leaving the storage tank, the consistency should be reduced by adding of white water (previously used water or rewater). Depending on the nature of pulp the inlet consistency of the screening equipment should be 0.35 to 0.85 for optimum result. When the consistency comes over the 0.85 percent, then the rejections will increases. The proper consistency of the stock ought to be 0.40 to 0.50 percent depending, on the type of pulp screening.

The diameter of the pulp screening equipment holes is another important variable for screening performance. In case of coarse screen it should not be more than 3/16 ins in diameter; but it is better to keep 1/8 ins in diameter. Whereas it ought to be 0.045 to 0.0625 ins in case of fine screen. It decides the minimum size of particle that will be rejected.

After fine screening the rejected stock may around 10%; it rejects such fibers that are not too coarse. Hence it may advice to rescreen the stock with the proper dilution to better recover. It may be coarse screen. The accepted stock of fine screening is excellent quality for supply to next stage.

The coarse screening removes the heavier particles such as very coarse fibers, knots, shives, dirt and sand and it may be 4 to 5 percent of the whole stock. It may differ basis on kinds of fiber and type of screening and the holes diameter. The accepted stock of coarse screening is send to the fine screening inlet side to rescreen for greater efficiency in screening section.

Besides pulp screening equipment, the screening section may contain centi-cleaner and filter for Different paper grades required different qualities of pulps. Centi-cleaners are used to separate the fine dirt from the fiber and to deliver a clean pulp suitable for bleaching.

Dear admin can u briefly explain what is hot stock screen and its purpose and substitute if aany?

We currently use a shaker table one step filtering process for our fiber pulp.We are a typ2 course fiber plant. what would be the recommended screener for our facility?