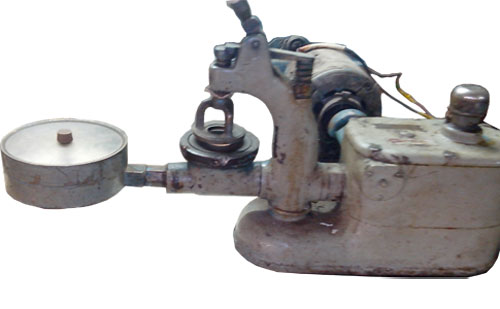

Bursting strength machine is used to test strength of the different kinds of paper and paperboard. The operating system of the tester is very easy. It is very important and widely used measurement. It is defined as the required minimum amount of hydrostatic pressure to rapture the paper or paperboard (maximum resistance (in kPa) of a specimen). The pressure is applied through a rubber diaphragm. This paper property is depends on many things like kinds of fiber, formation, chemicals, basis weight. It increases by using of long fiber, wet and dry strength additives, sizing chemicals etc. Bursting properties also increases with the degree of refining due to fiber to fiber bonding improvement. On the other hand it decreases by increased filler materials, secondary fiber and dried pulp. The test is also known as Mullen test because it is design by Mullen about 100 years ago. It is an oldest method for test the paper strength.

How to test the bursting strength

The paper bursting machine can be Hydraulic and pneumatic. It can be computerized or manual operating system. The tester has two clamps the lower clamp and upper clamp. The upper clamp has a diameter about 95 mm with a circular opening 31.5 mm in diameter whereas the lower clamp has circular opening 31.5 mm in diameter. The upper clam connects with a pivot joint so that it can create pressure to strongly hold the paper sheet. To perform the test, a sample of paper sheet is placed firmly between the lower clamp and upper clamp, and then provides pressure on the sample. The pressure is increased though the rubber diaphragm and hydraulic pressure until the sample burst. The pressure is generated though a motor, rotary pump or other suitable methods. Then record the reading of the pressure. The bursting strength of paper represent as kPa (kilo-pascal).

Burst index and burst factor of paper

The reports of the bursting strength of paper need to be submitted as burst index and burst factor. These two parameters are very important in packaging industries. According to ISO 536 the burst index means the bursting strength in kilopascals, divided by the basis weight in gsm. On the other hand the burst factor can be calculated with the bursting strength in gram per centimeter squire, divided by the basis weight in gsm.

Burst index = bursting strength/ basis weight = kPa/g/m2 = kPa.m2/g

Burst factor = bursting strength (g/cm2) / basis weight (g/m2)

Conclusion

We know that bursting strength indicates very significantly the quality of the paper and packaging materials. It also tells us, how much stress can be bear by the materials when we applied an external pressure. So in packaging industries, it is very important.

Give me a quotation of the following product for PAPER with detail information – GSM Cutter, GSM Weight , Thickness, moister, Brightness factor, Bursting factor, Opacity, Shade, Pulp, and Bulk (CC/GM).

Dear Sir

Interpac is new factory for paper production

Required Burst Tester for paper produced by our factory

Regards

Eng.Ahmed Abdellatif

New Fine Pac

Cairo ,Egypt