Alkaline extraction stage is essential after chlorination bleaching stage is to remove chlorinated and oxidizing lignin products from the pulp. It is also help to reactivate the remaining lignin for the next oxidation stage. All the chlorinated lignins are not soluble in the water. About 40-42% of them are soluble in water and wash out. Consequently, the rest of the chlorinated lignin products are not possible to remove. The rest insoluble parts of the products dissolve fairly readily in weak caustic soda solution under a certain condition. The required amount of caustic is directly related to the chlorine usage in earlier stage. Normally, it may be two-third of the chlorine usage. In this stage many modern bleaching plant add oxygen and hydrogen peroxide with caustic soda to get better result. The condition of oxygen and hydrogen peroxide usage are almost same as like as the condition of alkaline extraction. This stage is designated as E.

After chlorination bleaching stage a thorough wash is given to remove acidic and water soluble products. Otherwise the caustic uses will increase to neutralize the acidic products. Then, the alkaline extraction is carried through as an independent stage. Reaction time, consistency, temperature and amount of caustic applied depend on the quality of pulp required. The application of caustic should be uniformed so that it works well. It is better to use with a shower pipe. Additional caustic dosage can increase the effectiveness but it will also raise the overall bleaching expenses. On the other hand low dosage may affect on the solubilization. So pH maintain is very significant.

Condition:

In alkaline extraction stage the sodium hydroxide is added to the pulp at medium consistency, about 10-15%. The sodium hydroxide is added such an amount so that the final pH of the stock should be 10.5 to 11. The temperatures are maintained from 60⁰C to 80⁰C and the reaction time is 30 to 60 minutes. Some cases the reaction time reach up to 2 hours. If all the condition cannot maintain properly, then the solubilization may be incomplete.

Second alkaline extraction

Many bleaching plant carried second alkaline extraction. This stage is set out after the first hypochlorite or chlorine dioxide stage. After this stage a great amount of oxidized lignin may remains in the partial bleach pulp. About 50% reaction products of the first hypochlorite stage are water soluble. The rest are soluble in weak caustic and remove from the pulp. The solubility of the oxidized lignin can increase by alternating acid and alkaline bleaching action.

Oxygen reinforced alkaline extraction

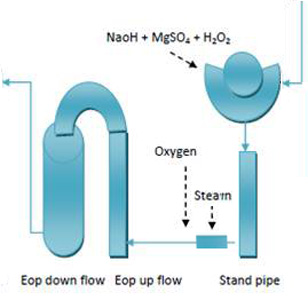

Currently, it is almost common practice adding oxygen and hydrogen peroxide to the pulp in Alkaline Extraction. The oxygen selectively reacts with remaining lignin and reducing the consumption of subsequent stage bleaching chemicals such as chlorine dioxide. A small amount of oxygen, about 10 lb per ton of pulp is sufficient for the action. The oxygen reinforced alkaline extraction stage is designated as EO whereas addition of peroxide for further reinforcement stage is designated as EOP. To create a pressure, normally a bleaching plant installs an upflow tower followed by a downflow tower.

Dear Sir,

We want to publish your technical article in our international newspaper The pulp and Paper Times with your Name Courtesy. The paper will go to 25 countries with 3000 circulation. We would like to collaborate with you…

Visit us : http://www.kagatrade.com a global online portal for pulp and paper Industry

Yes, you can do this with my website.

can sulphuric acid be added to maintain cl pH if yes what will be impct on forthcoming stages positive / negative

No, you can’t use sulfuric acid after chlorination bleaching stage because of:-

NaOH function in pulp bleaching is to control pH and what is another function except pH control. Is acceptable to have verify concentration of caustic strength during the bleaching process

How is brightness affect by caustic strength

NaOH is also help to reactivate the remaining lignin for the next oxidation stage. For the lignin reactivation, the brightness of the pulp is reduced.

Thank you

The NaOH reactivate the lignin for the next stage