Globally, there are several bleaching sequences are shown in different pulp mills to achieve the bleaching action. Different chemicals are used in each stage usually with washing between two stages to removes products. The preference of bleaching sequences depends on many things such as pulp categories, environment issue, operating cost, product quality of final bleached pulp. The sulfite pulps and hardwood Kraft pulps contains lower lignin, therefore it is easier bleaching than softwood Kraft pulps. On the other hands, non wood pulps are easily bleached compare to wood pulps; as a result shorter bleaching sequences are used in here such as CEH, CEHH. The bleaching of pulp with elemental chlorine and chlorine based chemicals has become a most important universal environmental problem. They produce many hazard organic compounds (such as organic halides) during bleaching process. Therefore, many leading pulp mills modify their bleaching sequences so that it can be decreased the impact on environment. The oxygen, ozone, hydrogen peroxide and Chlorine dioxide are more environmentally bleaching agent compatible to chlorine and they reduces significantly the consumption of chlorine. Oxygen is cheaper than Chlorine dioxide and hydrogen peroxide; hence it reduces the production cost.

Bleaching sequences can be divided into two segments depends on their function such as delignification segment and brightening segment. The function of delignification agent is to remove the lignin. Normally the initial stages of a sequence are delignification segment; the oxygen and chlorination stages are included in this segment. The main function of brightening agent is to raise the brightness of the pulp. The hypochlorite, Chlorine dioxide, hydrogen peroxide etc stages are included into this segment. Usually, the most of the brightening segment chemicals are highly selective chemicals (such as Chlorine dioxide and hydrogen peroxide) and that are used in later stages when the lignin content are low and the cellulose is vulnerable to degradation.

The commonly applied chemical treatments of pulp and their symbols are bellow.

Chlorination (C): Elemental chlorine reacts with pulp in acidic medium.

Alkaline extraction (E): Dissolution of reaction product with NaOH.

Chlorine Dioxide (D): Chlorine Dioxide reacts with pulp in acidic medium.

Oxygen (O): Molecular oxygen reacts with pulp in alkaline medium at high pressure.

Hypochlorite (H): Hypochlorite reacts with pulp in alkaline medium.

Peroxide (P): Peroxide react with pulp in alkaline medium.

Ozone (Z): In this stage Ozone reacts with pulp in acidic medium.

Chelats (Q): Chelating stage

Eo – extraction stage reinforced with oxygen

Eop – extraction stage reinforced with oxygen and hydrogen peroxide

X = enzymes stage

Y = hydrosulfite stage

Paa = peracetic acid stage

Pp – pressurized hydrogen peroxide stage;

q – Semi-chelating stage (conducted in not ideal conditions);

The most common bleaching sequences (using the above symbols) that are wildly used by the pulp and paper mills are CEH (for semi bleached pulp), CEHH, CHEH, CEHEH, CCHEHH, CED, CEHD, CEHED, CEHDD, CEHDH, CEDED,CEHDED, CCHEDH, CDEODED, OCDEHD, CEHEDP, CEDPD, CEDEHD. (DC)(EPO)DED, D(EPO)DED, (D/Z)(EPO)DED, OD(EPO)D, OD(EPO)DD, OD(EPO)DP, OD(EPO)DZ, O(Z/D)(EPO)DP, (C+D)EODED, DEODED, OZEOD, YP (two stage for mechanical pulp). Among them CEH, CEHH, CHEH are used for lower brightness pulps; CEHEH, CCHEHH, CED, CEHD, CEHED are used for medium brightness pulp (up to 85% GE brightness) and CEDED, CEHDED, CCHEDH, CDEODED, OCDEHD are used for high brightness (around 90 or 90 plus). Hydrogen peroxide containing bleach stage produce high brightness pulps for example CEHDP and CEDPD produce above 90 plus percent G.E brightness pulp.

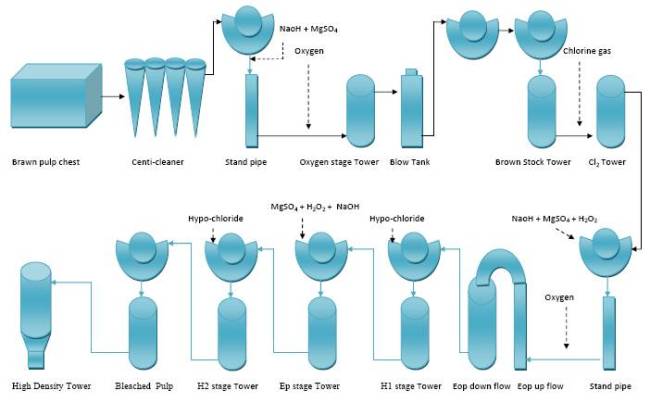

A bleaching sequence and their flow diagram are shown below:

Dear application/project manager.

We are looking after Pulp preparation plant of 50 Tons/day.

Raw material: Waste brown carton of box’s (it’s free in our place).

Bleaching it to white pulp, to make a recycle new white paper.

Can you supply such project, or support or help / advise us ??.

B.rgds,

Eng. Y. Rubinstein.