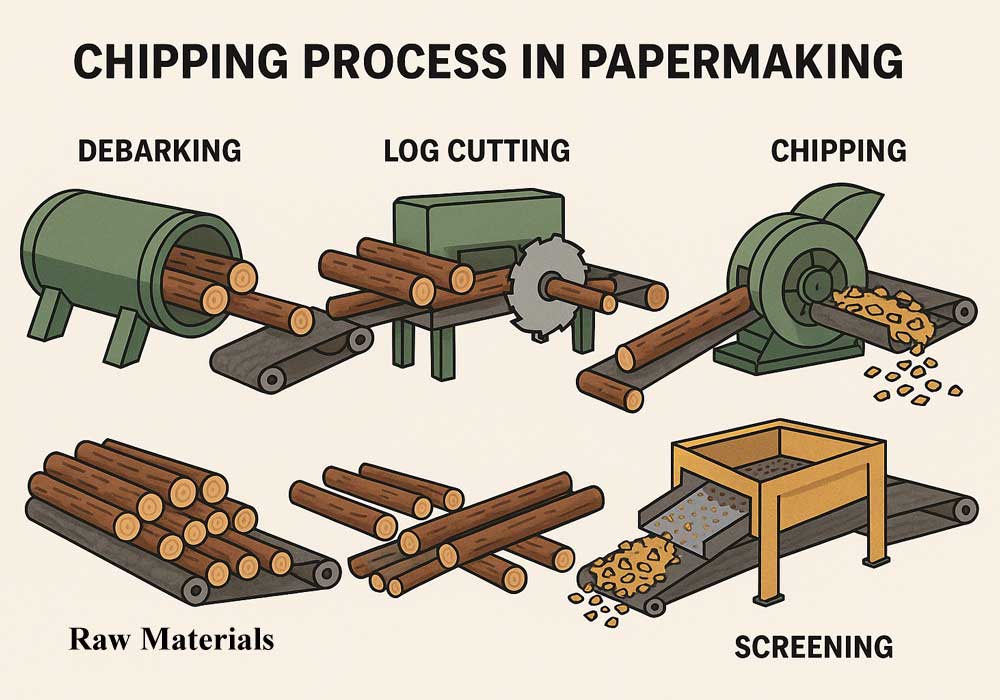

The chipping process in papermaking is a vital early stage in transforming raw wood into pulp—the foundation for paper production. Uniform wood chips promote efficient pulping and result in superior paper quality. This article explores each phase, including raw materials, debarking methods, log cutting, chippers (disc, drum, screw), screening, and the conveyors that tie it all together. Understanding these essentials empowers paper manufacturers to optimize operations, reduce waste, and support sustainability.

Raw Materials: Foundation of Quality

At the heart of the chipping process lies the raw material—wood. Common sources include:

- Whole logs, which are typically debarked and cut into shorter lengths before chipping.

- Wood residues, such as sawdust, shavings, or by-products from mills.

- Occasionally, recycled wood may be chipped and used in pulp production.

The choice between softwood (e.g., pine, spruce) and hardwood (e.g., birch, eucalyptus) matters significantly:

- Softwoods have long fibers, yielding strong and durable paper—ideal for packaging.

- Hardwoods offer shorter fibers, resulting in smoother, more printable papers like office and tissue grades.

Careful selection and preparation of raw materials ensure the final chip quality supports effective pulping and paper production.

Debarking: Removing Contaminants

Debarking is the initial mechanical step in preparing logs for chipping. Bark is a contaminant that, if left intact, can impair pulping quality and efficiency.

Methods include:

- Drum debarkers, which use rotating drums to strip bark from logs.

- Ring debarkers or high-pressure water jets, which are better suited to smaller-scale or more precise operations.

Through debarking, mills ensure that only clean, bark-free wood enters the cutting and chipping stage—setting the stage for consistent, high-quality chips.

Log Cutting: Preparing for Chipping

Following debarking, logs are too large for direct chipping and must be cut into manageable lengths.

This step ensures:

- Uniformity of log pieces for smooth processing.

- Consistent chip size since every log segment is similar in shape and size.

Machinery used:

- Mechanical log cutters.

- Saws, selected based on throughput and required precision.

Cutting logs uniformly also enhances safety, handling, and material flow throughout the chipping process.

Chipping: Transforming Logs into Chips

The chipper is the central machine in the process. Its job: slice logs into uniform wood chips suitable for pulping.

Types of chippers include:

- Disc chippers: Rotating steel discs with mounted blades slice the wood.

- Drum chippers: Use a rotating drum equipped with knives to produce chips.

- Screw chippers: Feed wood via a screw mechanism toward cutting blades.

Precise control of blade sharpness, feed rate, and chipper RPM ensures chips are uniform in size—critical for effective pulping. Poorly chipped logs can lead to inefficient pulping, higher energy use, and lower-quality pulp.

Screening: Ensuring Size Consistency

After chipping, the wood chips go through screening to filter out undesirable sizes. Vibratory screens and rotary screens separate the wood chips. Oversized chips, which are redirected back for further chipping and undersized particles (fines), often used as fuel or discarded.

Only properly sized chips proceed to pulping. This step is vital to maintain consistency, pulping efficiency, and overall paper quality.

Conveyors: The Circulatory System

Throughout the chipping process, conveyors play a pivotal role in material transport:

- They move logs between debarking and log cutting.

- They transport cut logs to the chipper.

- They carry chips through screening to storage or pulping.

Automated conveyor systems synchronize with other machinery to ensure a smooth, continuous flow—enhancing operational efficiency and reducing manual handling.

Machinery Overview Table

| Phase | Machinery | Purpose |

| Debarking | Drum/ring debarkers, water jets | Remove bark to reduce contaminants |

| Log Cutting | Mechanical cutters, saws | Cut logs into uniform lengths |

| Chipping | Disc, drum, or screw chippers | Produce wood chips of consistent size |

| Screening | Vibratory or rotary screens | Filter chip sizes; separate fines and oversize |

| Conveying | Belt, chain, or automated | conveyors Move materials between stages |

Advantages and Sustainability

The chipping process delivers several benefits:

- Efficiency: Uniform chips improve pulping speed and chemical penetration.

- Quality Control: Screening ensures only ideal chip sizes proceed to pulping.

- Waste Reduction: Oversized chips are re-chipped; fines may be repurposed, minimizing disposal.

- Automation: Conveyor integration streamlines operations with reduced labor.

Sustainability efforts include:

- Using wood residue or recycled material to conserve resources.

- Optimizing machinery for reduced energy consumption.

- Recovering fines for biomass fuel or internal reuse.

Conclusion

The chipping process in papermaking is a foundational stage that shapes the efficiency and quality of pulp production. From carefully selecting raw materials and debarking logs to precision chipping, screening, and conveying, every step contributes to uniform, contaminant-free wood chips. These ensure streamlined pulping, superior paper quality, and operational sustainability. By continuously refining each component—whether debarkers, chippers, screeners, or conveyors—paper manufacturers can boost productivity, reduce waste, and foster eco-friendly practices. Understanding and optimizing each phase empowers the industry to produce better paper with less environmental impact.