Paper touches nearly every part of modern life—books, packaging, tissues, cartons, food boxes, office sheets, and more. But few people understand what “pulp,” “paper,” and “paperboard” actually mean or how they differ.

This article breaks down these essential materials in a clear, simple way. Whether you’re a student, buyer, manufacturer, or sustainability researcher, you’ll find an easy-to-follow explanation of how pulp is made and how it becomes paper or paperboard. We’ll also explore real-world applications, sustainability facts, and the future of fiber-based packaging.

What Is Pulp?

Pulp is the raw fiber material used to make paper and paperboard. It is primarily derived from:

- Wood (softwood or hardwood)

- Recycled paper

- Agricultural residues (bagasse, straw, bamboo)

- Non-wood plants (cotton linters, hemp)

At the microscopic level, pulp is made of cellulose fibers, which bind together when pressed and dried, forming sheets of paper.

Types of Pulp

- Mechanical Pulp: Produced by grinding wood logs into fibers.

- High yield: 90–95% of the wood is used

- Lower strength

- Yellowish (lignin remains)

- Used for: newsprint, magazines, catalogs, directories

- Chemical Pulp: Wood chips cooked with chemicals to remove lignin. Kraft Pulp (sulfate process) is the most common chemical pulp.

- Lower yield: 45–55%

- Stronger and longer fibers

- Used for: writing paper, packaging grades, tissue paper

- Recycled Pulp: Made from collected wastepaper.

- Environmentally friendly

- Cost-effective

- Used for: corrugated boxes, carton board, tissue, molded fiber packaging

- Semi-chemical Pulp: Combination of chemical treatment + mechanical refining.

- Balanced strength

- Used for: corrugated medium in cardboard boxes

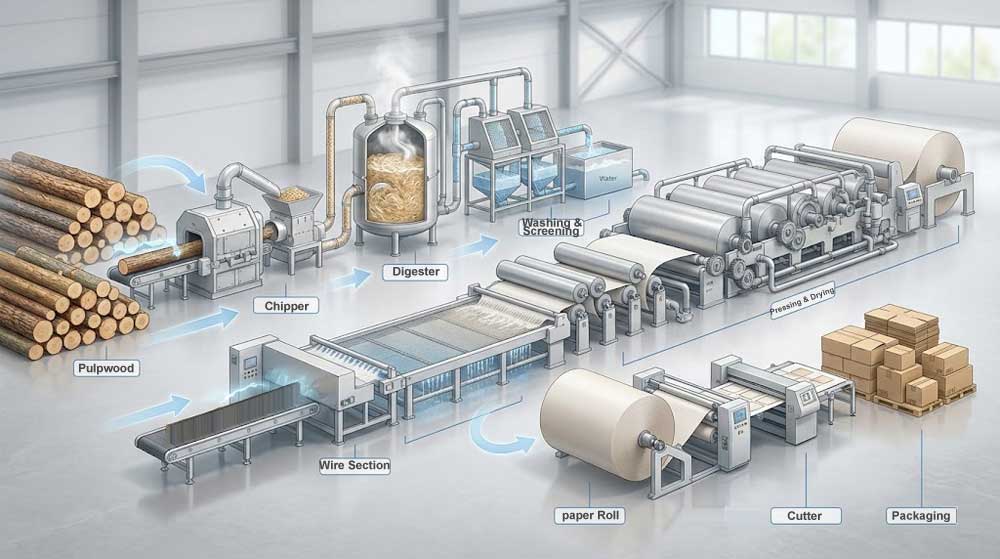

How Is Pulp Made? (Step-by-Step)

- Raw Material Preparation: Logs are debarked and chipped into uniform pieces.

- Pulping Process: Depending on type:

- Mechanical: refining or grinding

- Chemical: cooking in digesters with chemicals

- Recycled: pulping in hydrapulpers with water

- Washing & Screening: Removes impurities such as bark, sand, shives, staples, and ink.

- Bleaching (Optional): Used for high-brightness papers. Modern mills use ECF (Elemental Chlorine Free) or TCF (Totally Chlorine Free) technologies.

- Stock Preparation: Chemicals such as sizing agents, fillers, and dyes are added.

- Paper Machine Formation: Fibers are laid on a moving screen (wire section) to form a sheet.

- Pressing & Drying: Water is removed through rolls and steam-heated dryers.

- Finishing: Coating, calendering, cutting, and packaging the final product.

What Is Paper?

Paper is a thin sheet material made from interlaced cellulose fibers. It is typically:

- Less than 200–250 gsm

- Flexible, smooth, and printable

Most daily products—copy paper, notebooks, tissue, newspapers—fall under this category.

Common Types of Paper

- Writing & Printing Paper

- Newsprint

- Tissue Paper

- Coated Paper

- Specialty Papers (filter, thermal, decorative)

What Is Paperboard?

Paperboard is a thicker, stronger, multi-ply fiber material used for packaging and industrial applications. It usually ranges from:

- 250 gsm to 600+ gsm

- 0.3 mm to 1.5 mm thickness

- Paperboard is the base material for:

- Cereal boxes

- Shoe boxes

- Food packaging

- Folding cartons

- Liquid cartons (milk/juice)

- Graphic printing boards

Types of Paperboard

1. Solid Bleached Sulfate (SBS)

- Made from bleached chemical pulp

- Pure white board

- Premium printing quality

- Used for cosmetics, pharmaceuticals, high-end packaging

2. Folding Box Board (FBB)

- Multi-layered construction

- Virgin fibers + mechanical pulp

- Lightweight and stiff

- Widely used for consumer packaging

3. Coated Recycled Board (CRB)

- 100% recycled fibers

- Economical

- Used for food trays, simple packaging, toys, tissue boxes

4. Kraft Board

- Strong brown packaging board

- Ideal for e-commerce packaging

- Excellent tear resistance

5. Liquid Packaging Board

- Coated with plastic or aluminum

- Used for milk, juice, and aseptic packs

Paper vs Paperboard: Key Differences

| Feature | Paper | Paperboard |

| Thickness | Thin (<250 gsm) | Thick (250–600+ gsm) |

| Strength | Moderate | High |

| Use | Writing, printing, tissue | Packaging, cartons, boxes |

| Layers | Usually single-ply | Multi-ply |

| Printing | High quality for coated papers | Excellent for cartons |

Applications of Pulp, Paper & Paperboard

Everyday Uses

- Books, notebooks, envelopes

- Napkins, toilet tissue, kitchen towel

- Product packaging

- Paper bags

Industrial Uses

- Corrugated cartons

- Pharmaceutical packaging

- Food-grade boards

- Liquid cartons

- Kraft paper for heavy-duty sacks

Innovative Uses

- Molded fiber packaging (Apple packaging style)

- Sustainable e-commerce packaging

- Biodegradable food trays

- Fiber-based straws

Sustainability & Environmental Importance

The global pulp and paper industry is moving toward greener practices:

- Over 50% of paper worldwide is made from recycled fibers.

- Certified forests (FSC/PEFC) ensure responsible wood sourcing.

- Modern mills cut CO₂ emissions using bio-energy from black liquor.

- Biodegradable paperboard is replacing single-use plastics in packaging.

Paper is one of the most recyclable materials on Earth—recycled up to 5–7 times before fiber quality declines.

Conclusion

Pulp, paper, and paperboard form the backbone of global communication, packaging, and sustainable materials. Understanding how these products are made—and how they differ—helps industries choose the right grade for printing, packaging, or specialty applications.

As the world shifts to eco-friendly materials, fiber-based packaging continues to play a leading role. Whether you’re a manufacturer, student, or business buyer, pulp and paper remain essential, evolving materials for a greener future.

FAQs

1. What is pulp in paper manufacturing?

Pulp is the cellulose fiber material obtained from wood, recycled paper, or plants used to make paper and paperboard.

2. What is the difference between paper and paperboard?

Paper is thinner and used for printing or writing, while paperboard is thicker and used for packaging.

3. Is paperboard the same as cardboard?

Not exactly. Paperboard is a general material; cardboard usually refers to corrugated board used for shipping boxes.

4. What types of pulp are used in the industry?

Mechanical, chemical, recycled, and semi-chemical pulps are the most common.

5. Is paper sustainable?

Yes. Paper is recyclable, biodegradable, and often sourced from certified sustainable forests.

6. What is SBS paperboard used for?

SBS (Solid Bleached Sulfate) is used for premium packaging such as cosmetics, medicine, and luxury cartons.

7. How many times can paper be recycled?

Typically 5 to 7 times, after which fibers become too short.