In the paper industry, the transformation of raw wood into usable pulp begins with one indispensable machine: the industrial wood chipper. While household chippers handle garden waste, industrial wood chippers are built for large-scale operations, designed to process entire logs into uniform chips. These chips are the primary raw material in papermaking, making wood chippers one of the most critical machines in modern pulp and paper mills.

This article explores how logs are processed, the different types of industrial wood chippers, and their pivotal role in papermaking, highlighting why they remain essential to efficiency, sustainability, and product quality in the global paper industry.

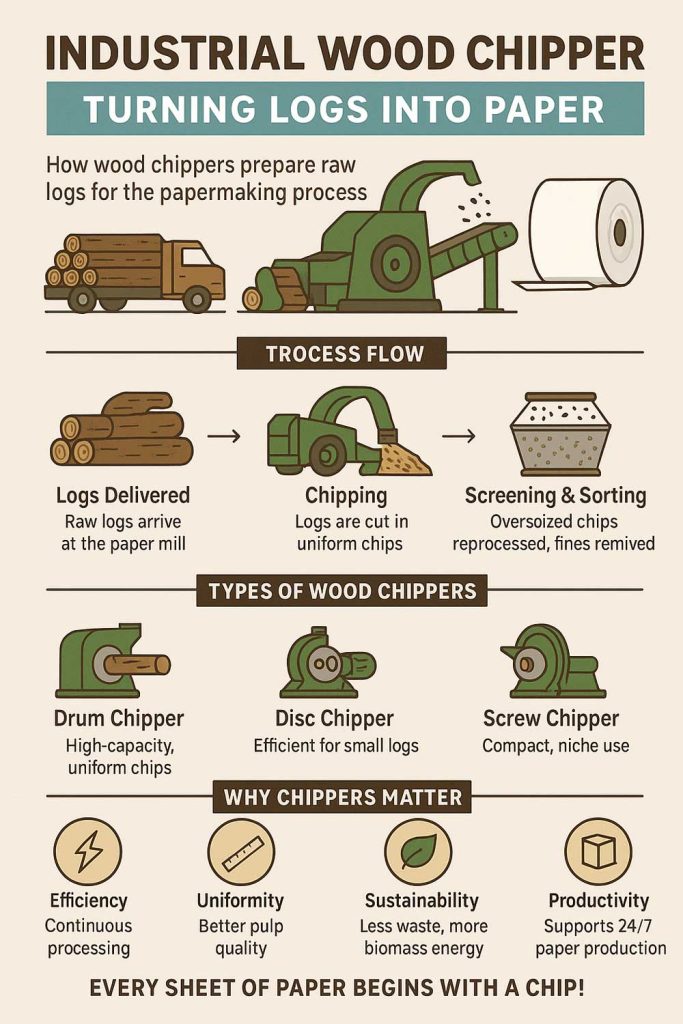

How Logs Are Processed in Paper Mills

Before wood can be converted into pulp, it must be prepared in a form suitable for chemical or mechanical treatment. Industrial wood chippers perform this crucial task:

Log Delivery and Preparation

- Logs are transported from forests or plantations to the mill.

- Debarking machines remove bark, as it contains impurities and reduces pulp quality.

Feeding Logs into the Chipper

- Logs are fed via conveyors or loaders into the chipper’s cutting system.

- Automated feeding ensures consistent chip size and prevents jamming.

Chipping Process

- High-strength steel knives slice logs into chips, typically 2–5 cm long and 2–10 mm thick.

- The goal: produce uniform chips for efficient pulping.

Screening and Sorting

- Oversized chips are re-chipped.

- Undersized chips (fines) are removed, as they can cause poor pulp quality.

Storage and Transport

- Finished chips are stored in silos or piles before moving to the pulping line.

By ensuring uniformity, industrial wood chippers directly influence paper strength, brightness, and production efficiency.

Types of Industrial Wood Chippers

Industrial wood chippers come in several designs, each with unique advantages depending on mill capacity and chip quality requirements.

1. Drum Chippers

- How they work: A rotating drum fitted with knives cuts wood against a counter blade.

- Advantages: High throughput (ideal for large logs). Produces consistent, high-quality chips.

- Common use: Large-scale pulp and paper mills.

2. Disc Chippers

- How they work: A flywheel-like disc with mounted knives slices logs into chips.

- Advantages: Efficient for smaller logs and branches. Lower maintenance compared to drum chippers.

- Common use: Medium-capacity mills and smaller plants.

3. Screw Chippers

- How they work: A conical screw pulls logs inward, cutting them into chips.

- Advantages: Compact design. Suitable for specialized applications.

- Common use: Less common in papermaking, more in niche wood processing.

Horizontal Feed vs. Vertical Feed Chippers

- Horizontal feed: Easier to handle long logs, safer operation.

- Vertical feed: Preferred for smaller pieces or scrap wood.

Role of Industrial Wood Chippers in Papermaking

Wood chippers are not just machines; they are gatekeepers of pulp quality. Their role extends far beyond cutting logs:

- Ensuring Chip Uniformity: Uniform chip size ensures even chemical penetration during the pulping process, improving yield and reducing chemical consumption.

- Reducing Waste: Modern chippers maximize wood utilization, turning almost the entire log into chips. Bark and sawdust can even be diverted to biomass energy systems within the mill.

- Boosting Efficiency: By automating log processing, mills can achieve continuous, 24/7 production cycles. This supports the paper industry’s demand for massive daily outputs.

- Sustainability and Eco-Efficiency: With growing focus on sustainability, chippers enable the use of fast-growing plantation wood and even residues from sawmills. Efficient chipping reduces the carbon footprint of paper production.

Industrial Wood Chippers and the Future of the Paper Industry

The global paper industry is evolving to meet the demand for eco-friendly packaging, recycled paper, and biodegradable products. Industrial wood chippers play a vital role in this transformation:

- Integration with Biomass Energy: Residual bark and fines can fuel biomass boilers, making mills energy self-sufficient.

- Smart Chipping Technology: AI-controlled feeding systems ensure optimal chip size and reduce knife wear.

- Sustainability: Use of plantation-grown eucalyptus and bamboo requires specialized chippers designed for smaller-diameter logs.

As digitalization and sustainability reshape paper manufacturing, industrial wood chippers remain at the core of innovation.

Conclusion

The industrial wood chipper is a cornerstone of the paper industry. By transforming raw logs into uniform chips, these machines enable efficient pulping, reduce waste, and support sustainable practices. Whether it’s a heavy-duty drum chipper handling massive logs or a disc chipper serving medium-sized mills, the chipper’s role is indispensable.

As the paper industry embraces green technology and digital optimization, industrial wood chippers will continue to evolve—ensuring that every sheet of paper starts with a clean, efficient, and sustainable cut.

FAQs on Industrial Wood Chippers in Papermaking

Q1: Why are wood chips important in papermaking?

Because chip size and uniformity determine pulp quality, yield, and chemical efficiency.

Q2: Which is better for paper mills: drum or disc chipper?

Drum chippers are preferred in large-scale mills due to their higher capacity and uniform chip production.

Q3: Can wood waste be used in paper production?

Yes. Sawmill residues, offcuts, and even recycled wood can be chipped and used in certain pulping processes.

Q4: Do wood chippers impact sustainability?

Yes. By maximizing log usage and reducing waste, they make papermaking more eco-friendly.